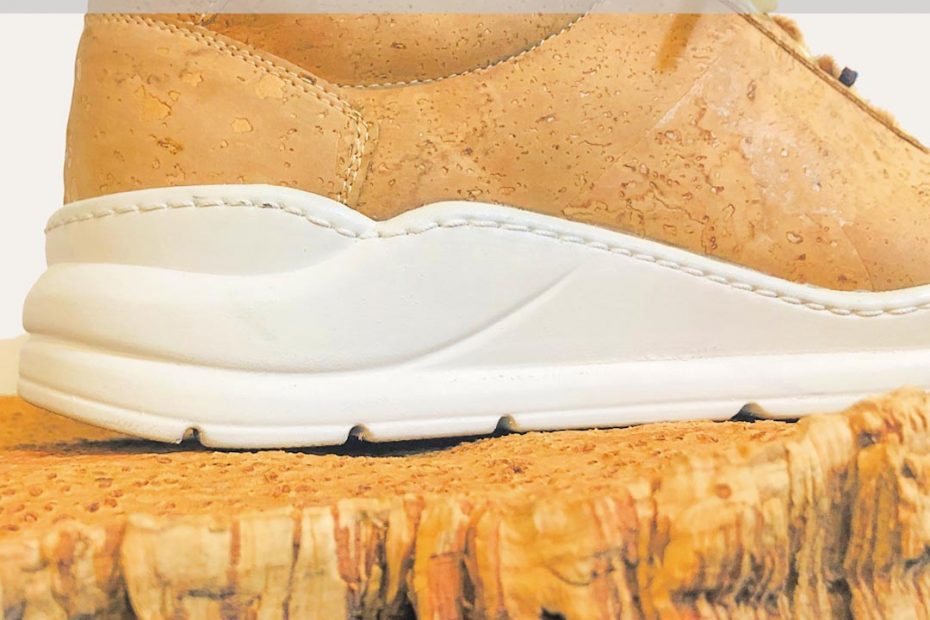

Materials for shoe soles. What are they made with?

The fact that there are many types of shoes, used for unlimited different purposes make us think about the differences in the materials and manufacture processes they are involved. This post is about shoe soles. Do you know how the soles of top quality shoes are made?

Materials according to type and purpose

Depending on the type of shoe and its purpose, there are several types of material you can manufacture quality shoe soles. Thanks to research carried out in specialized footwear development and research centers such as CCTP (centro tecnológico do calçado português), every day the materials we manufacture soles are being improved and expanded. It is obvious that footwear intended for sports will have a very different type of sole than a non-sport or informal shoe, or even the shoe used for certain jobs such as construction. This means the materials for shoe soles vary according to their purpose.

Soles specially designed according to the type of shoe

When we talk about materials for shoe soles we cannot stop thinking that depending on the purpose, the soles must have a series of specific characteristics. For example, if the type of footwear is more sporty, the sole must provide elasticity and resistance, so the material used for this type of sole must fulfil this task. In this case, the rubber is usually the most used use. Bellow you can find a list of the most common shoe soles materials.

Rubber Soles

To get soles made from rubber, technology enters the scene to synthetically obtain this type of shoe sole. Rubber has the advantage of its elasticity, although it is true that they must also comply with regulations to be resistant to both abrasion and the breaking point in terms of flexion. The main advantage of rubber for shoe soles is it is a material that weakens impacts and prevents slipping, regardless of the aforementioned elasticity. It should not be too soft to give it consistency and depending on its manufacture (the thermoplastic paste made with molds and rubber compound granules can vary its final result depending on the needs …) we can improve shock absorption, durability and resistance.

Thermoplastic rubber (TR) soles.

A very often material used to manufacture soles is TR. The soles made with thermoplastic rubber are used to make almost any type of shoe, boots, wedges or clogs and sports shoes. TR has elements that makes it very versatile, as it is flexible and elastic, so its purpose is very broad. Usually the price for thes soles is more affordable.

TPU soles

TPU is another material widely used in the manufacture of soles. Thermoplastic polyurethane offers greater benefits than other types of materials for shoe soles. The soles made of TPU, are very flexible and comfortable, in addition and they recognized for nor slipping. This type of sole is widely used for work boots and sports shoes. Manufacturing can be done by applying several layers, the first layer to offer cushioning and flexibility, and another layer to the denser interior that is in contact with the ground.

EVA soles

EVA, or also called vinyl acetate sole, is one of the best materials in terms of lightness that we can find on the market today. It combines various characteristics such as shock absorption lightness. The downside is that it is very slippery, so it is not often used as a “top coat” for a sole. In sports shoes, specifically for running shoes, it is usually used as an intermediate layer since it absorbs shocks very well and makes the final weight of a shoe very light.

Sustainable soles made with reused materials

With the improvement of the footwear technology new material can now be incorporated in shoe shoes. Soles composed of recovered, reused and recycled materials are now a big trend in the market due the increase of social awareness in sustainability issues. Reused plastic bottles, reused tennis balls and even coffee grounds are now a possibility to have in our shoes. These materials are usually mixed with rubber and can represent 20%-50% of the composition of the soles decreasing the environmental impact of producing a shoe.

At treec we proudly use in some of our models waste from the coffee production. We are committed to committed to have positive footprint and make and impact the way we use our everyday shoes.